In today’s competitive rice industry, delivering clean, uniform, and high-quality rice is essential to meet consumer demands and international food safety standards. Traditional manual sorting methods are time-consuming, inconsistent, and costly. This is where Rice Sortex Machines revolutionize the process.

At Manitech Instruments Pvt. Ltd., we specialize in cutting-edge optical sorting technology that enhances efficiency, reduces waste, and ensures only the best rice reaches the market. In this blog, we’ll explore how Rice Sortex machines work, their advantages, and why they are a must-have for modern rice millers and processors.

What is a Rice Sortex Machine?

A Rice Sortex Machine is an AI-powered optical sorter that uses high-resolution cameras, advanced algorithms, and precision air ejectors to detect and remove defective grains, foreign particles, and discolored rice. It ensures zero human error, delivering 99.9% pure rice in a single pass.

How Does a Rice Sortex Machine Work?

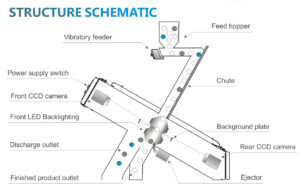

Feeding System – Rice is evenly distributed via a vibratory feeder to ensure smooth flow into the scanning area.

High-Speed Optical Scanning – Dual-camera technology captures multiple images per grain, analyzing color, size, shape, and defects in milliseconds.

AI-Based Decision Making – Sophisticated software compares each grain against preset quality parameters to identify:

Broken or immature grains

Discolored, fungal, or diseased grains

Foreign materials (stones, husks, glass, plastic)

Precision Ejection System – Defective grains are removed instantly using high-speed air jets, ensuring only premium rice moves forward. Products

Key Benefits of Using a Rice Sortex Machine

1. Unmatched Sorting Accuracy (99.9% Purity)

Eliminates all impurities—including tiny defects that manual sorting misses.

Ensures uniform grain size and color, enhancing market appeal.

2. High-Speed Processing Product Parameters

Processes 4x faster than manual labor, boosting productivity.

Ideal for large-scale rice mills and export-oriented processing plants.

3. Significant Cost Savings

Reduces labor costs by up to 70% compared to manual sorting.

Minimizes grain loss—only defective grains are removed, maximizing yield.

4. Improves Export Market Compliance

Meets international food safety standards (FDA, EU, FSSAI).

Helps rice millers command premium prices in global markets.

5. Multi-Grain Sorting Capability MULTIFUNCTIONALFULL COLOR SORTER

Works not just for rice but also:

Wheat, pulses, quinoa, sesame seeds, and coffee beans ,Plastic , Groundnut etc.

Adjustable settings for different grain types.

Watch out the latest videos of Manitech instruments color sortex machine YouTube

6. Low Maintenance & Hygienic Operation

Stainless steel construction for durability and easy cleaning.

Self-cleaning nozzles prevent clogging and ensure continuous operation.

Case Study: How a Rice Mill in Chhattisgarh Increased Efficiency & Quality

One of our valuable clients, Bholenath Rice Mill (Bhatapara, Chhattisgarh), was facing challenges with manual sorting, high impurity levels, and slow production. After installing our Rice Sortex Machine they achieved:

✅ Drastic improvement in grain purity and color quality

✅ Sorting speed increased

✅ Reduced labor dependency

✅ Boosted market reputation and customer satisfaction

“The performance of Manitech’s color sorter exceeded our expectations. Sorting accuracy, consistency, and output quality have all improved remarkably. It’s a game-changer for our business.”

— Mr. Aditya Sharma, Bholenath Rice Mill YouTube

Why Choose Manitech Instruments Pvt. Ltd.?

We are India’s leading manufacturer of optical sorters, trusted by 500+ rice mills and food processors. Here’s why customers prefer us:

✔ Advanced AI & Dual-Camera Technology – For ultra-precise defect detection.

✔ Customizable Solutions – Different models for small, medium, and large-scale mills.

✔ 24/7 Technical Support – Installation, training, and maintenance assistance. Contact Us

✔ Competitive Pricing – Best-in-class machines at affordable rates.

Industry Trends: The Future of Rice Sorting

With rising global demand for premium rice, automated sorting is no longer optional. Key trends include:

🔹 AI-powered defect recognition for even higher accuracy.

🔹 IoT-enabled sorters for real-time performance monitoring.

🔹 Sustainable sorting with energy-efficient models.

Manitech is at the forefront, integrating smart technology into our machines to keep you ahead of the competition.

Conclusion

A Rice Sortex Machine is a game-changer for rice millers, ensuring higher profits, lower waste, and superior quality. At Manitech Instruments Pvt. Ltd., we provide state-of-the-art sorters tailored to your needs.