Wheat is one of the world’s most consumed grains, playing a vital role in the food processing and agricultural industries. For businesses involved in wheat processing, quality assurance is a top priority. Manual sorting is time-consuming and error-prone. That’s where a wheat color sorter machine comes in—a smart, efficient, and cost-effective solution.

In this complete guide, we’ll explore how a wheat color sorter machine works, its advantages, use cases, and why it’s an essential investment for agro-industries . YouTube

What is a Wheat Color Sorter Machine?

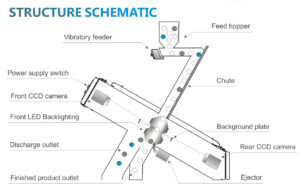

A wheat color sorter machine is an optical sorting Machine that automatically detects and removes defective, discolored, or contaminated wheat grains. It utilizes high-resolution CCD cameras, intelligent image processing software, and precision ejectors to ensure only the best-quality grains are selected.

Why Use a Wheat Color Sorter Machine? Product Parameters

1. Enhanced Product Quality

Discolored or damaged wheat can degrade the final product’s appearance and taste. A wheat color sorter machine helps deliver consistent quality by removing:

- Black tips

- Moldy grains

- Insect-damaged kernels

- Broken or immature grains

- Foreign particles like stones and husk

2. Higher Sorting Accuracy

With AI and optical sensors, these machines sort grains with up to 99.9% accuracy. This minimizes contamination, ensuring high-grade output every time.

3. Boosted Efficiency and Productivity

Color sorters process thousands of grains per second—far more than any manual method. This accelerates your operations and reduces downtime.

4. Cost Reduction

By reducing dependency on manual labor and increasing throughput, businesses save significantly on operational costs.

5. Compliance with Export Standards

Meet international safety and hygiene standards with precise sorting, enhancing your product’s marketability globally.

How Does a Wheat Color Sorter Machine Work?

- Feeding: Wheat grains are loaded into the hopper.

- Vibration: A vibrating tray ensures uniform grain distribution.

- Imaging: High-resolution cameras scan each grain.

- Analysis: The software compares grain colors to programmed parameters.

- Ejection: Compressed air nozzles remove the unwanted grains.

Key Features to Look For RGB Colour Sorter Machine

- High-resolution CCD or NIR sensors

- AI-enabled defect detection

- Multi-layer sorting

- Touchscreen interface

- Remote monitoring and diagnostics

- Multi-language support

Types of Wheat Color Sorter Machines Products

Based on Capacity

- Small-Scale Units: 0.5 – 1 ton/hour

- Mid-Scale Units: 1 – 3 tons/hour

- Large-Scale Units: 5+ tons/hour

Based on Technology

- RGB-based

- Full-color RGB + IR

- AI-powered color sorters

- Multispectral optical sorters

Applications of Wheat Color Sorter Machine

- Flour Mills: Ensure clean, high-grade input.

- Seed Processing Units: Separate viable seeds from waste.

- Export Houses: Meet international quality standards.

- Food Processing Plants: Improve end-product quality.

- Government Agencies: Maintain procurement quality for PDS.

Why Choose Manitech Instruments? About Us

- Pan-India presence

- Real-time customer support

- User-friendly systems

- Multigrain sorting compatibility

- Competitive pricing and financing options

Client Success Stories

1. Rajasthan Nakoda Wheat Mill: Improved productivity by 35% using Manitech’s high-speed wheat sorter. 2. MP Grain Exporter: Achieved compliance for export using MPlus wheat color sorter.

Installation & Support

Manitech offers full-service support:

- Site surveys

- Installation

- Operator training

- Preventive maintenance

- 24/7 remote diagnostics

FAQs

Q: Can one machine sort multiple grains? A: Yes, Manitech machines sort rice, dal, chana, peanuts, seeds , plastics and more.

Q: What is the power requirement? A: 1kW to 10kW depending on the model.

Q: Can it be operated by non-technical staff? A: Absolutely. It features a touchscreen and simple interface.

Q: Warranty? A: Standard 1-year warranty with extension options.

Conclusion

A wheat color sorter machine is a powerful investment for any agro-based enterprise. It enhances quality, saves costs, increases efficiency, and supports market growth. With AI integration and precision sorting, Manitech Instruments delivers future-ready solutions for India’s grain industry.

Choose innovation. Choose reliability. Choose Manitech. Best Rice Color Sorter Machine in India 2025 | Manitech Instruments